With so many new innovations being made within the television industry, it can be difficult to keep up with all the latest technologies. One of the most recent and exciting developments in TV manufacturing is the introduction of Inorganic LED. This technology looks set to revolutionise the way in which we watch TV in the coming years.

There are currently no displays of this kind in mass production however, tech giants Samsung suggest we are set to see this technology released to consumers and used more widely in the coming years.

In this article, we will take a closer look at what exactly inorganic LED is and how this technology compares to the OLED technology that is currently available.

What is Inorganic LED?

Inorganic LED, also referred to as microLED, is set to transform the way we watch television once it is mass produced and available to consumers. Originally first invented by research group Professor Hongxing Jiang and Professor Jingyu Lin of Texas Tech University in the year 2000, Inorganic Semiconductor micoLED technology displays were initially aimed at small, low-energy devices such as Smartwatches and Smartphones.

Similar to Organic Light Emitting Diodes (OLEDs), inorganic LEDs are self-emitting and so do not require a back light. They use inorganic materials such as GaN (Gallium Nitrate), which is also found in conventional LEDs for lighting.

The fibres are extremely small, typically they are 1/10th of the width of a human hair enabling manufacturers to deposit them as pixel arrays on a substrate in order to make a display.

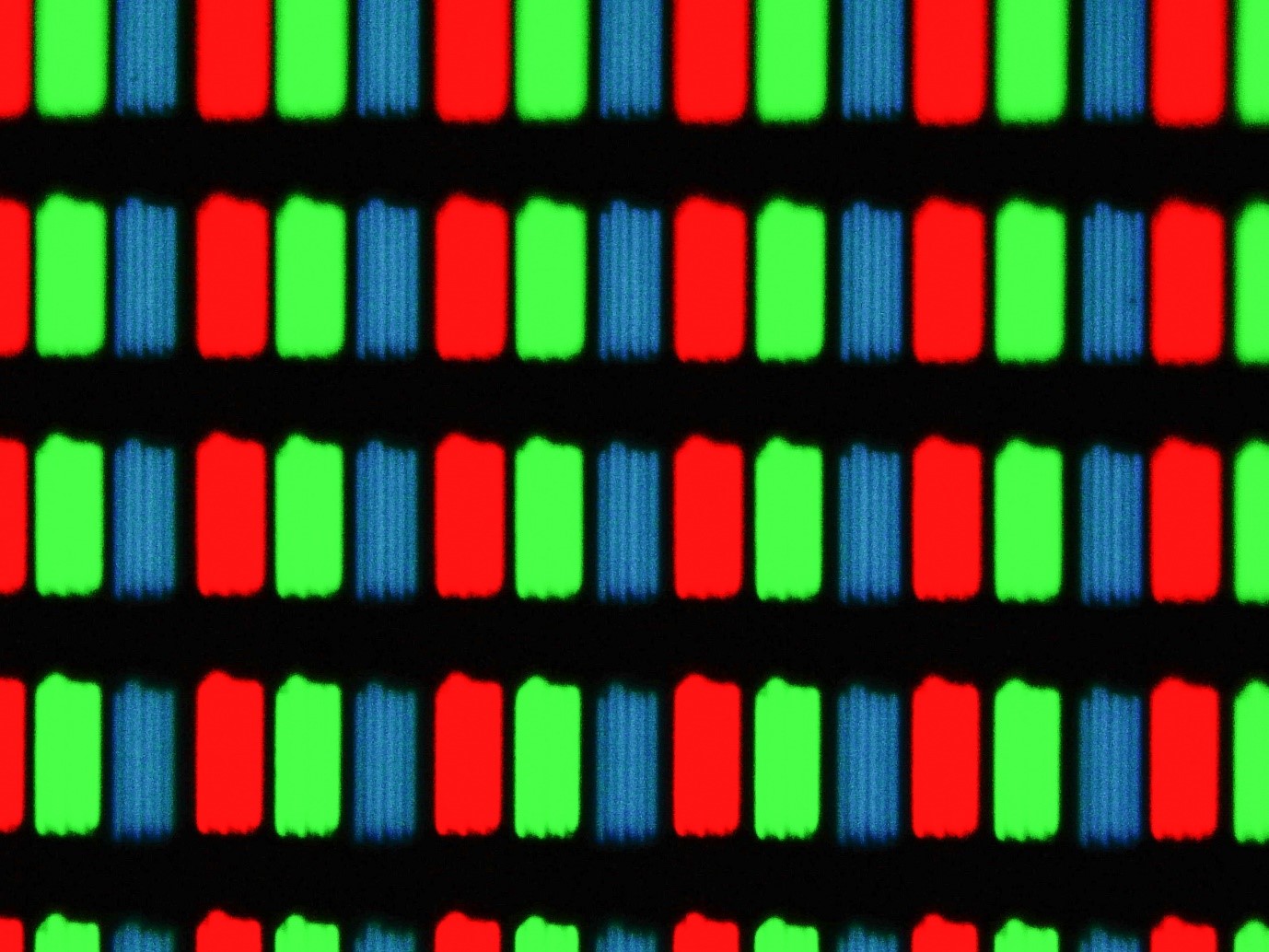

Using these very small LEDs to create subpixels, depending on how light form the subpixels is mixed (generally made up of one green, one red and one blue), they can produce any given colour, not dissimilar to display technologies already in existence. This also includes the ‘darker black’ feature we have become accustomed to following the production of OLEDs.

Again, much like current display technologies, inorganic LED uses TFT (thin film transistor). A feature relating to microLED calls upon the fact that the light diodes need a passive colour filter over the top to reproduce required colours.

OLED vs Inorganic LED

MicroLED and OLED share a lot of similarity, including the ability to produce deep blacks, high contrast, high colour gamut and quick response times.

With that said, inorganic LED produces higher brightness and is a great deal more stable because of its inorganic nature, meaning it will not be affected by luminance decay issues. OLED pixels suffer this decay at varying speeds.

Another advantage of inorganic LED is that it is more energy efficient, requiring less energy to power the microLED pixels, whilst still achieving a powerful viewing experience.

At CES 2018, Samsung showcased their first MicroLED TV, ‘The Wall.’ Whilst the intention of this screen is to be produced and used as large cinema screens, they suggest that the display is able to be customised to different sizes and shapes, dependent on the needs of the consumer. However, the company have yet to produce a downsized version of the screen, whilst maintaining pixel density to produce 4K resolution on the smaller scale.

Once manufacturers are able to mass produce an inorganic LED display on a smaller scale, this will change the way we watch TV. No longer will consumers need to think about viewing distances etc. because with these microscopic pixels, the viewing distance can be much less without having an impact on resolution or viewing experience.

Here at Electronic World, we stock a wide range cheap TVs from some of the world’s most respected TV manufacturers. From cheap 4K TVs through to the latest cheap curved TVs, we have a fantastic range of TVs available and are constantly updating our website with the very latest TVs on the market.